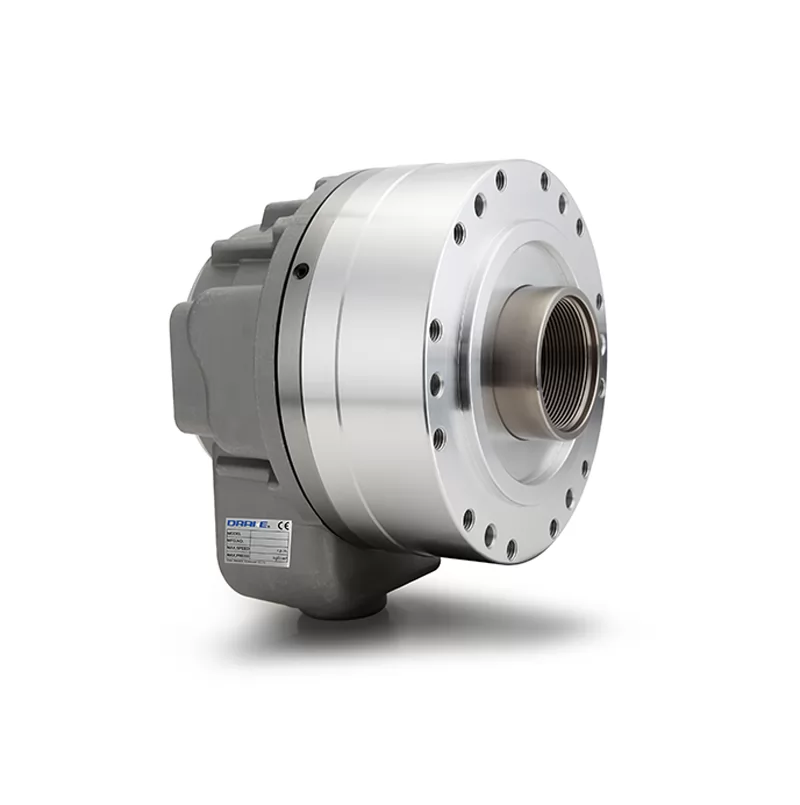

Product Details

The HY420B hydraulic steady rest utilizes the hydraulic system of a CNC lathe.

This system, unlike hydraulic presses, grinders, and construction machinery, primarily performs auxiliary movements required for part machining.

The force and flow required for these auxiliary movements vary minimally.

Its primary loads are providing clamping and tightening force for machined parts, cutting head locking, cylinder shifting, and slide balance at high tilt angles.

In reality, most CNC lathe hydraulic steady rests are friction-supported or roller-type, requiring manual adjustment.

The three support claws on the steady rest must be manually adjusted to align with a circle.

This approach also has its drawbacks, such as being cumbersome to use and subject to potential errors in accuracy.

In practice, this centering method is not entirely reliable, often relying on the operator's experience and feel.

As the frequency of hydraulic steady rests used on CNC lathes increases, the number of manufacturers of these products is increasing.

As a long-established company with many years of experience, our company possesses unique skills in product production and development.

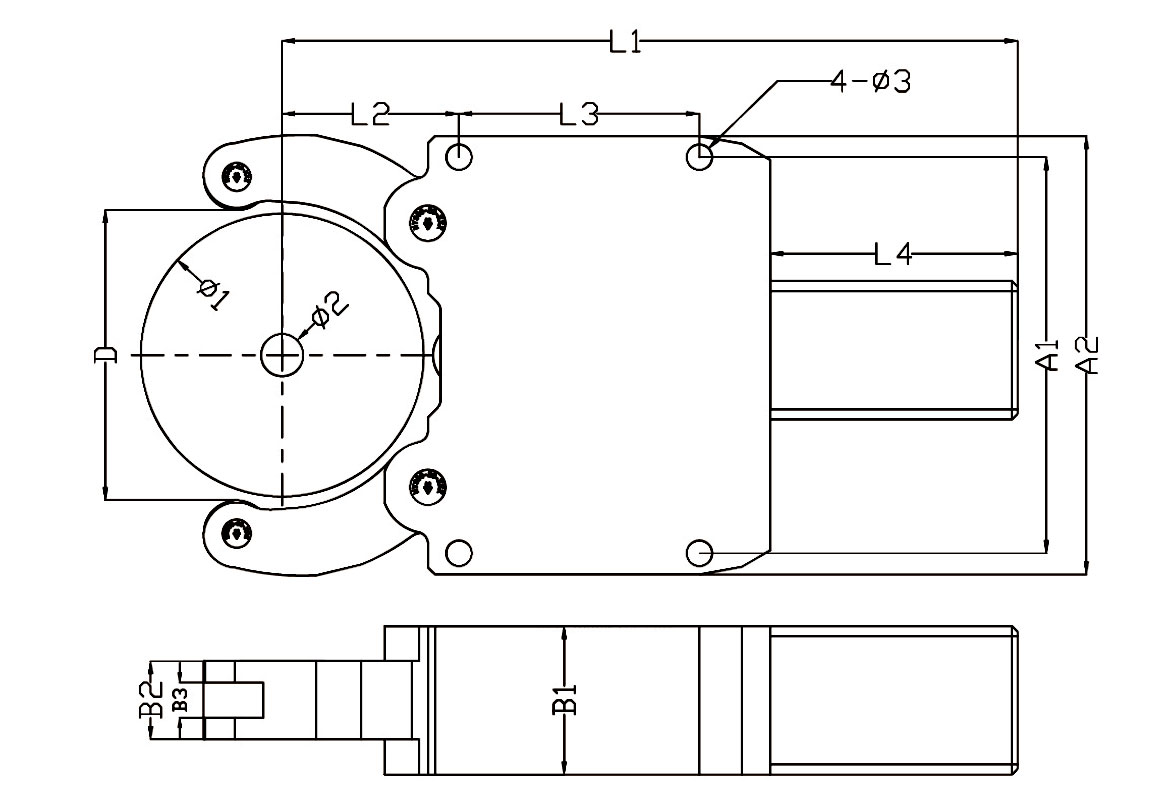

Product Size

Product Parameters

| HY-B(C) series center stand specifications, dimensions and technical performance parameters | |||||||||

| Model | HY115B | HY170B | HY220B | HY260B | HY310B | HY350B | HY420B | HY520C | HY650C |

| Clamping diameter range | φ15-φ115 | φ20-φ170 | φ40-φ220 | φ35-φ260 | φ50-φ310 | φ75-φ350 | φ115-φ420 | φ150-φ520 | φ250-φ650 |

| L1(mm) | 279 | 394 | 479 | 517 | 550 | 600 | 648 | 658 | 798 |

| L2(mm) | 83 | 116 | 136 | 157 | 177 | 229 | 258 | 278 | 403 |

| L3(mm) | 92 | 160 | 202 | 230 | 270 | 240 | 270 | 315 | 300 |

| L4(mm) | 55 | 60 | 60 | 60 | 30 | 30 | 30 | 30 | 35 |

| A1(mm) | 190 | 258 | 341 | 360 | 400 | 461 | 440/475 | 560/680 | 750/625 |

| A2(mm) | 215 | 285 | 372 | 392 | 442 | 499 | 510 | 750 | 812 |

| B1(mm) | 85 | 95 | 110 | 110 | 125 | 125 | 136 | 155 | 175 |

| B2(mm) | 45 | 55 | 60 | 60 | 75 | 75 | 72 | 95 | 95 |

| B3(mm) | 15 | 25 | 25 | 25 | 29 | 29 | 29 | 32 | 32 |

| φ1(mm) | 115 | 170 | 220 | 260 | 310 | 350 | 420 | 520 | 650 |

| φ2(mm) | 15 | 20 | 40 | 35 | 50 | 70 | 115 | 150 | 250 |

| φ3(mm) | 14 | 18 | 18 | 22 | 22 | 22 | 22 | 22 | 26 |

| D(mm) | 118 | 176 | 226 | 268 | 311 | 355 | 420 | 520 | 655 |

| Working Pressure (MPa) | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 |

| Working Range Centering Accuracy | 0.03 | 0.04 | 0.05 | 0.05 | 0.06 | 0.06 | 0.07 | 0.08 | 0.09 |

| Repeat | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.02 | 0.02 |

| Net Weight (kg) | 23 | 48 | 88 | 94 | 138 | 168 | 198 | 318 | 438 |